|

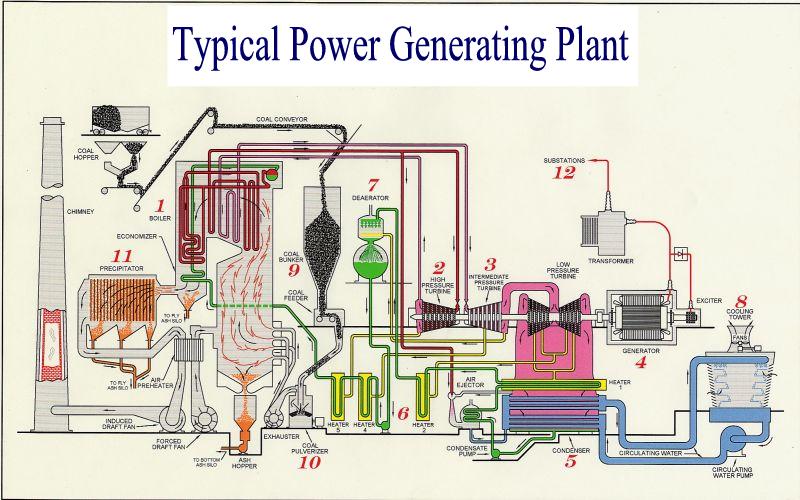

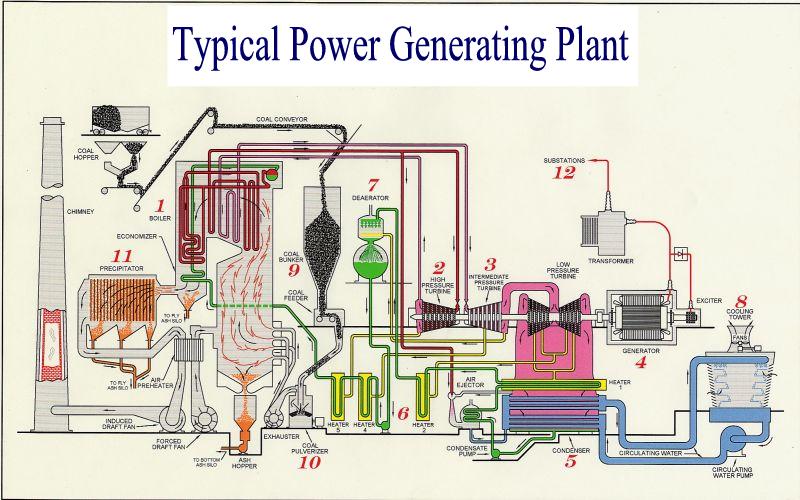

Explore how electric power is generated. Click on the numbers in the image below to discover different function at the typical power plant.

|

No. 1 - The Boiler

This typical boiler is constructed of approximately 300

miles of special high temperature steel tubing supported by a steel I-beam

frame. The steel tubes are filled with water. Heat inside the

boiler boils the water, and they steam is collected at the top of the boiler.

The steam then flows to the turbine. Ash is collected at the bottom of the

boiler and precipitator, where it is conveyed to an ash collection system.

Coal handling system

This Generating Station burns coal delivered by train.

Coal is delivered to the plant in rail cars that hold 100 tons each. Once

the coal is delivered to the plant, it is unloaded by coal handlers and either

stored in a stock pile for future use or is transferred via coal conveyors into

the plant for immediate use.

No. 2 - High

pressure turbine

The high pressure turbine primarily consists of fan-type blades attached to a

shaft. Steam flows against the blades, causing the shaft to turn.

No. 3 -

Intermediate and low pressure turbine

The intermediate and low pressure turbine, while constructed like the high

pressure turbines, are designed to add efficiency to the cycle.

No. 4 - The generator

The shaft of the generator is connected to the turbine shaft. When the

turbine rotates the generator, electricity is produced.

No. 5 - Condenser

Steam leaves the turbine, and is admitted to the condenser, where it is cooled

by circulating water. The steam is condensed, and water is pumped back to

then boiler.

No. 6 - Heaters

The heaters are used to heat the water on its return back to the boiler.

Small amounts of steam are removed from the turbine at different pressures to

heat the water.

No. 7 - Deaerator

One of the heaters is called the Deaerator because, in addition to heating the

water, it removes air and other dissolved gases from the water.

No. 8 - Cooling tower

The cooling tower is used to cool the circulating water. This is done by

lowing air across water that is falling through the cooling tower.

Circulating water

pumps

These pumps are used to transfer water from the cooling tower to the

condenser and back to the cooling tower.

No. 9 - Coal bunker

Coal is delivered to the Generating Station by rail. Belt conveyors

are used to transfer the coal to the storage bunkers.

Coal feeders

The coal feeders measure the amount of coal that is required to make steam and

generate power as required by our customers. Coal flow to the boiler

varies as the amount of electricity used varies.

No. 10 - Coal

pulverizer

The coal flows by gravity into the pulverizers from the coal feeders.

When the coal is in the pulverizer, it is ground into the approximately fineness

of talcum powder. It is then blown into the furnace, where it mixes with

air, and burns at bout 2500 degrees Fahrenheit.

Fans

The boiler has two large fans. The forced draft fan blows air into the

boiler so that coal will burn and produce heat to produce steam and the induced

fan pulls gases from the boiler and precipitator.

No. 11 - Precipitator

The electrostatic precipitator eliminates 99.6% of the fly ash from the boiler

flue gases by means of many fine wires and static electricity, so that smoke

from the chimney will be eliminated.

Chimney

The chimney is the final destination of the coal combustion process. It is

typically over 400 feet tall. Boiler controls and plant operators carefully control the

fuel combustion process to keep emissions to a minimum and to ensure that the

maximum amount of heats is extracted from the coal as possible.

Transformer

Electricity from the generator (13,400 volts) travels to the main step up

transformer. It is then converted to 115,000 volts.

No. 12 - Substations

Electricity that is generated will be sent to various satellite substations

located strategically in the electric distribution system. From there, the

circuits are used to transmit electricity to all of our customers:

industrial, commercial, irrigation, rural and residential.